Hydraulic vibration compactor is also called hydraulic plate compactor, excavator plate compactor, excavator vibration compactor, etc. Hydraulic vibration compactor is a new technology and new process that has gradually become popular in countries around the world in recent years, and the vertical vibration technology is selected. The technology was first applied to vibratory rollers by Sakai Heavy Industries of Japan, and achieved good practical results. Since then, this technology has also been applied in some construction machinery and equipment in my country, and a series of rolling machines of different models and specifications have been developed successively, such as hydraulic vibratory compactors.

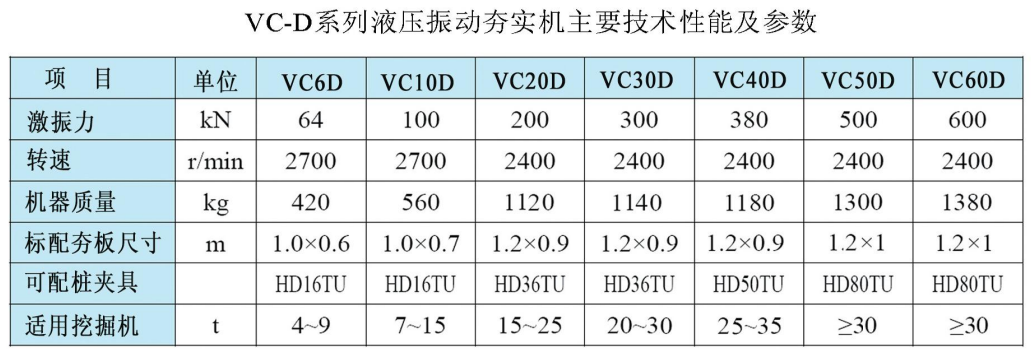

1. VC6D hydraulic vibration compactor has an exciting force of 64KN, a rotational speed of 2700r/min, a machine mass of 420kg, a standard compaction plate size of 1.0*0.6m, and a pile fixture HD16TU, suitable for 4~9t excavators;

2. The VC10D hydraulic vibration compactor has an exciting force of 100KN, a rotational speed of 2700r/min, a machine mass of 560kg, a standard tamper plate size of 1.0*0.6m, and a pile fixture HD16TU, suitable for 7~15t excavators;

3. VC20D hydraulic vibration compactor has a vibration force of 200KN, a rotational speed of 2400r/min, a machine mass of 1120kg, a standard tamper plate size of 1.2*0.9m, and a pile fixture HD36TU, suitable for 15~25t excavators;

4. VC30D hydraulic vibration compactor has an exciting force of 300KN, a rotational speed of 2400r/min, a machine mass of 1140kg, a standard tamper plate size of 1.2*0.9m, and can be equipped with a pile fixture HD36TU, suitable for 20~30t excavators;

5. VC40D hydraulic vibration compactor has an exciting force of 380KN, a rotational speed of 2400r/min, a machine mass of 1180kg, a standard tamper plate size of 1.2*0.9m, and can be equipped with a pile fixture HD50TU, suitable for 25~35t excavators;

6. VC50D hydraulic vibration compactor has an exciting force of 500KN, a rotational speed of 2400r/min, a machine mass of 1300kg, a standard tamper plate size of 1.2*1m, and a pile fixture HD80TU, suitable for ≥30t excavators;

7. The VC60D hydraulic vibration compactor has an exciting force of 600KN, a rotational speed of 2400r/min, a machine mass of 1380kg, a standard tamper plate size of 1.2*1m, and a pile fixture HD80TU, suitable for ≥30t excavators.

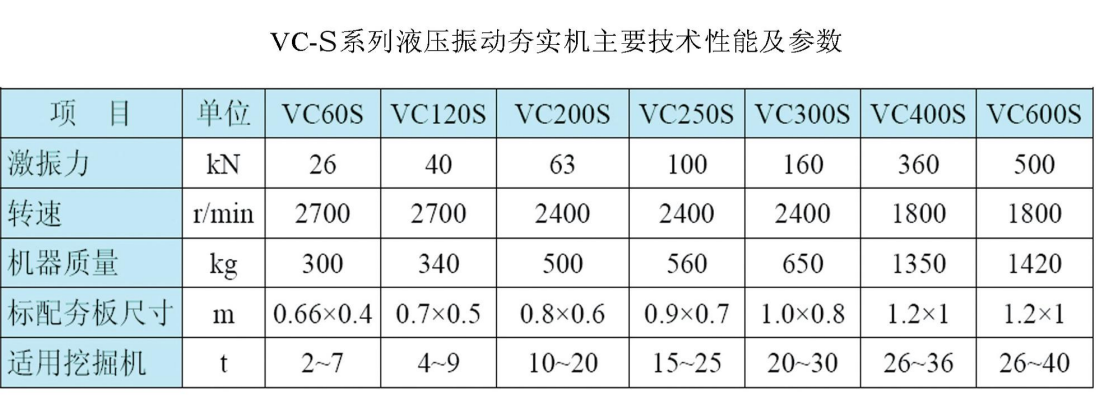

1. VC60S hydraulic vibration compactor has an exciting force of 26KN, a rotational speed of 2700r/min, a machine mass of 300kg, and a standard tamper plate size of 0.66*0.4m, suitable for 2~7t excavators;

2. VC120S hydraulic vibration compactor has an exciting force of 40KN, a rotational speed of 2700r/min, a machine mass of 340kg, and a standard tamper plate size of 0.7*0.5m, suitable for 4~9t excavators;

3. VC200S hydraulic vibration compactor has an exciting force of 63KN, a rotational speed of 2400r/min, a machine mass of 500kg, and a standard tamper plate size of 0.8*0.6m, suitable for 10~20t excavators;

4. VC250S hydraulic vibration compactor has an exciting force of 100KN, a rotational speed of 2400r/min, a machine mass of 560kg, and a standard tamper plate size of 0.9*0.7m, suitable for 15~25t excavators;

5. VC300S hydraulic vibration compactor has an exciting force of 160KN, a rotational speed of 2400r/min, a machine mass of 650kg, and a standard tamper plate size of 1.0*0.8m, suitable for 20~30t excavators;

6. VC400S hydraulic vibration compactor has an exciting force of 360KN, a rotational speed of 1800r/min, a machine mass of 1350kg, and a standard tamper plate size of 1.2*1m, suitable for 26~36t excavators;

7. The VC600S hydraulic vibration compactor has an exciting force of 500KN, a rotational speed of 1800r/min, a machine mass of 1420kg, and a standard tamper plate size of 1.2*1m, suitable for 26~40t excavators.

Compared with traditional road roller machinery, hydraulic vibratory compactors have the following advantages:

(1) High compressive strength and great cooperation. The mechanical equipment of the traditional road roller adopts the single rack circular vibration compaction method, and the centrifugal azimuth rotates 360°. Flutter forces can be translated into vertical angles and horizontal directions. The horizontal shaking of the rapper greatly reduces the vertical flutter force. Such vibratory methods can cause the fill material to become crowded and compacted. The vertical rapper does not have horizontal interference force, and the vertical azimuth is the flutter synergy, and the compaction and compressive strength are high.

(2) The compaction quality is high, the depth is large, and there is no need for static grinding. Under the same tonnage of mechanical equipment and the same compaction frequency, the compaction degree of the hydraulic vibratory compactor can be increased by 3-5%, and the bearing capacity of the road surface can be increased by more than 30%; the compaction thickness can be more than doubled compared with the general vibratory roller; At the same time, after compaction, the surface layer has no loose layers, no cracks, and high flatness, so it is not necessary to roll again by static rolling.

(3) Incorporating various landforms and working methods. Hydraulic vibration compactor can realize plan compaction, slope compaction, step compaction, pipe groove dent compaction and its complicated and basic compaction solutions. It can be used for pile foundation construction at the same time, and can be used for pulling out piles, crushing, etc. after assembling the tooling fixture.

The hydraulic compactor with vertical vibration compaction technology has many advantages, such as high compressive strength, high efficiency, great damage to the depth, and excellent rolling processing technology. In this paper, with the help of Fan Hui's high-speed test ramming, the scientific research on the application technology of hydraulic vibration compactor in the backfill of the bridge bottom platform is carried out. According to the data analysis of the settlement amount and compaction degree of the cement soil foundation in different compaction time ranges, it shows that the hydraulic vibration compactor can reduce the uneven foundation settlement between the cover plate culvert and the approach embankment, and can effectively improve the backfill soil at the back of the platform. The compaction degree can reasonably prevent the bridge head from jumping. It is suggested that 40~50s is appropriate for the ramming time of hydraulic vibration compactor at the backfill of the platform.

The vibration exciter is a mechanical device installed on the compaction machine to generate the exciting force. When the exciter is working, the excited object can obtain a certain form and size of vibration. The vibration form of the exciter has a great influence on the compaction effect.

1 circle vibration

Circular vibration exciters are widely used in vibratory compaction machinery such as vibratory rollers and small vibratory plate compactors. The circular vibration exciter is a single eccentric structure. When the eccentric wheel rotates, the direction of centrifugal force (F) is always the direction away from the center of rotation, and rotates 360°. Under the combined action of the machine's gravity, the trajectory of the center of mass is similar to an oblate circle, which is called circular vibration, as shown in Figure 1. The circular vibration is actually the circular motion of the well-known eccentric object, and the exciting force is the centrifugal force. When the phase angle of the center of mass of the eccentric is different by 180°, the direction of the centrifugal force is opposite to that of the initial position, and the center of mass is located on the opposite side of the center of rotation, so it can also be called a generalized reciprocating motion. The vibration exciter drives the compaction components (such as the tamping plate of the vibratory rammer, the compaction wheel of the road roller) to vibrate, and transmits force and motion through the compaction components. During the compaction operation, the force of the circular vibration exciter can be decomposed into the excitation force in the vertical direction and the disturbance force in the horizontal direction. Obviously, the horizontal force of the exciter causes the compacted parts and the excited particles to oscillate. This movement deviating from the vertical direction interferes and weakens the effect of the vertical direction, and at the same time causes harm to adjacent structures and people and animals. In a vibration cycle, the compaction components are in a vertical or substantially vertical motion state only for a short period of time, and the trend of horizontal motion or horizontal motion is obvious in the remaining period of time, so the effective effect on soil particles is obviously biased. Low. Due to the oscillation of the circular vibration exciter when it is working, the machine is not running smoothly, and the amplitude is generally small.

2 vertical vibration

The vertical vibration exciter adopts a paired eccentric wheel structure, and the left and right eccentric wheels rotate synchronously in opposite directions. When the eccentrics rotate, the centrifugal forces (F1, FP2) in the horizontal direction of the left and right eccentrics cancel each other out, and the resultant force of the centrifugal forces in the vertical directions of the left and right eccentrics excites soil particles through the compacting parts. The direction of the force and the direction of motion of the exciter is always perpendicular to the layup, known in the industry as vertical vibration. The mode shape of vertical vibration is a simple linear reciprocating motion, known as vibration in the direct sense. The exciter can be rotated at any angle and has different effects on the layup. The so-called vertical vibratory rollers, oscillating (horizontal vibration) rollers, intelligent vibratory rollers, etc., which have been praised in the industry in recent years, the difference lies in the different placement angles of this type of vibration exciter.

Since the vertical vibration exciter does not have the horizontal disturbance effect of the circular vibration exciter, when the amount of the exciter (frequency, amplitude, excitation force) is the same, the compaction thickness and productivity of the vertical vibration compaction machine are significantly better than those of the circular vibration exciter. Compaction machinery has less adverse effect on adjacent structures than circular vibration compaction machinery, and the energy saving effect is also obvious. A certain type of 20t-class vertical vibratory road roller travels back and forth twice on the cohesive expansive soil, and the compaction degree exceeds 97%. The compaction degree that this machine can achieve is 5%~10% higher than that of the circular vibratory roller, the compaction efficiency is more than doubled, the compaction thickness is more than doubled, and the comprehensive energy saving is over 70%. Ramshen VC30D large-amplitude vertical hydraulic vibration compactor can still achieve a compaction degree of 97% to 99% when the layer thickness is 500mm.

- Hengda Machinery Co., Ltd

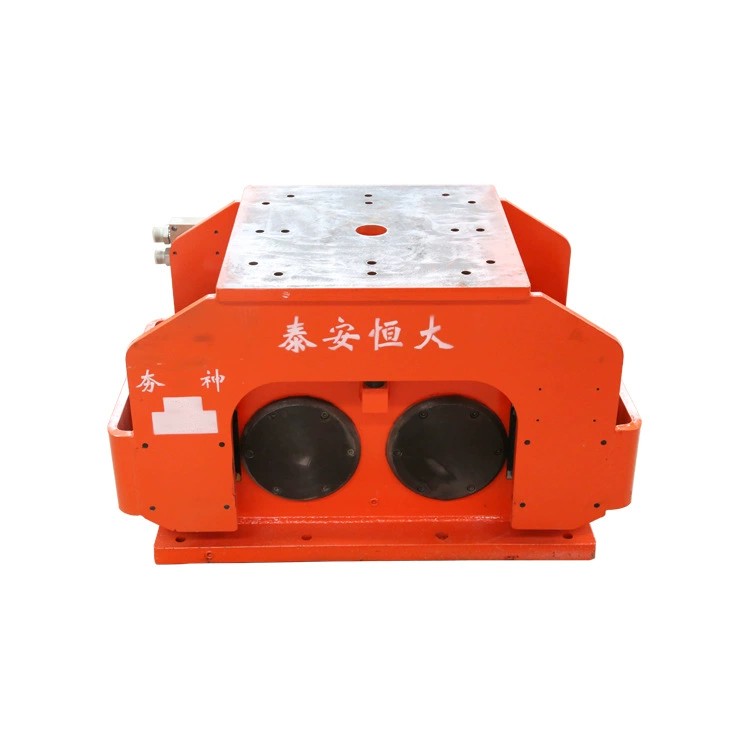

Plate Compactor for excavator